The Problem

In 1940 America was rearming for World War II. One of the many tasks was providing thousands of aerial gunners to protect the vast bomber fleets that would flow from America’s aircraft factories. Since very little had been done to train aerial gunners between the wars, the services were essentially starting from scratch.

Gunnery training was not simply a matter of putting a man behind a gun in an airplane and telling him to shoot at a target. Extensive ground training in weapons maintenance, firing and sighting techniques, as well as survival in flight, was required before a student gunner ever left the ground.

The Army Air Forces and the Navy were casting about for devices that would help to teach gunnery, and a number of ideas were tried. Aircraft machine guns and ammunition were in very short supply early in the war. Many devices involved dummy weapons, either hand pointed or mounted on a dummy turret, to aim at moving targets projected onto a screen in front of the gunner, and usually involved scoring methods that enabled both instructors and students to recognize and identify aiming errors so that they could be corrected.

One of the devices that was adopted was a small compressed air machine gun that fired standard BBs. It was originally developed as an amusement device, intended for use in arcade shooting galleries. It seemed like a natural for primary indoctrination of student gunners, and, after a few design improvements, it was adopted by the AAF as the Aerial Gunnery Trainer Type E-3 in July of 1941.

The MacGlashan Air Machine Gun

Because no single definitive and comprehensive history of the MacGlashan machine guns has been found, and probably does not in fact exist, what follows has been compiled from a number of manuals, books, reports and magazine articles, most of which are listed in the Bibliography. Appreciation is hereby expressed to their respective authors.

The first known appearance of the MacGlashan Company was in 1937, when it started manufacture of a BB air rifle.

Coming,history of the MacGlashan family, the MacGlashan Air Gun Company, and of the development of the guns.]

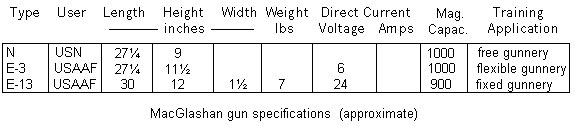

Various models of MacGlashan compressed air machine gun were produced. The first were made for use by shooting galleries at amusement arcades. With the advent of World War II, three models were produced for the U.S. armed forces for use in aerial gunnery training. They were:

The MacGlashan machine gun needed three things: electricity, compressed air, and a supply of BBs.

Electricity was supplied from regular 110-volt ac power through a power pack unit that converted it to 24 volts DC . Compressed air, in a pressure range of 60 to 200 psi, was provided by a separate air compressor that normally supplied all the guns at a range installation via a manifold. BBs were conventional commercial .177 caliber copper-coated steel shot.

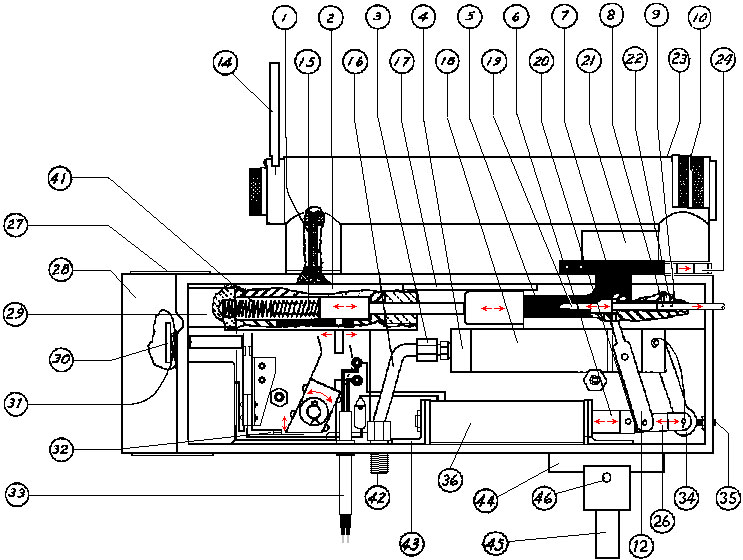

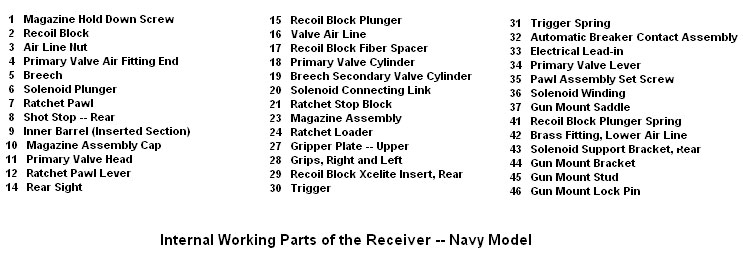

When the trigger was pulled (actually, a switch was closed) power flowed to an electrical solenoid that moved a couple of levers to perform several functions. First and foremost, it opened a valve that admitted compressed air to a piston. This pushed the piston to the rear, which withdrew a plug and allowed compressed air to enter the breech and fire a BB. Second, it actuated a rotary ratchet driven disc that was similar in function to the cylinder of a revolver. It had ten holes in it, each of which conveyed a BB from a tubular magazine to a point immediately above the breech, at which point it was pushed downwards into a short vertical feed tube by a spring-loaded ball detent that also held the disc in position. The vertical feed tube held four BBs, and whenever a BB was fired, a replacement dropped into the breech. A spring-loaded detent projected into the barrel just far enough to retain the BB until sufficient air pressure built up behind it to propel it down the barrel.

The piston also pushed a spring-loaded recoil block to the rear. This block, as it neared the limit of its backward travel, opened a breaker switch in the firing circuit which de-energized the solenoid, allowing it to return to its original position. This closed the air valve, allowing the spring-loaded piston to move forward and plug the rear of the breech. The recoil block also, by virtue of its mass and inertia, provided timing for the firing cycle, since it took a finite time interval for it to move back and then forward again. As it moved forward it closed the firing circuit, enabling the entire cycle to start again. The shaking produced by the longitudinal motion of the various moving parts probably helps the flow of BBs from the magazine into

the feed mechanism.

Timing is critical in the proper operation of the gun. Specifically, it is essential that power (electric and compressed air) remain on until the BB has left the barrel and the recoil cycle is well under way. Also, it is important that power not be restored until the moving parts are almost back in battery (forward position). This is controlled by the relationship between the recoil block and the breaker switch. The details of the breaker switch actuation varied from model to model

The cylindrical body of the primary valve has a reservoir capacity of about one cubic inch of compressed air, assuring that an ample volume is immediately available for operating the gun, not limited by the small-diameter supply line.

Ballistics Simulation

Since one purpose of the BB machine gun was to familiarize the gunner with the characteristics of the actual machine guns he would be firing, some thought was given to at least partially simulating the ballistic performance of the .30 caliber machine gun. It turns out that the angular gravity drop of a BB at 1,000 inches closely approximates that of a cal. .30 M1 bullet at a range of 556 yards if the BB’s muzzle velocity is just over 600 feet per second. The muzzle velocity can be controlled by adjusting the air pressure.

Since 556 yards is 20 times 1,000 inches, a scale factor of 1/20 was chosen. Since it is physically impossible to simulate simultaneously both the gravity drop and the required lead angle, the former was chosen. The Navy astutely solved this dilemma by displacing the front sight laterally so that the sight line was offset from the bore axis. Thus the student gunner visually applied the full long-range .30 caliber lead using his sights, while actually applying only the smaller lead to the gun that was required to score hits with the short-range BBs. Since the targets moved at a constant speed in the same direction and at the same range, they could get away with this solution.

MacGlashan provided the following ballistics data:

Muzzle velocity: 609 feet per second

Time of flight to 1000 inches: 0.21 second

Range, inches 500

750

1000

Drop, inches 0.4 1.1 2.2

With gun fixed in vise, an average of 74% of shots fired will group within 8½ inch circle on 1000 inch range.

The physics of gravity drop would seem to require a muzzle velocity substantially higher than 609 fps in order to produce the stated drop distances. That said, the data are presented for whatever they may be worth.